Automated Wagon Stability Analysis using Computer Vision

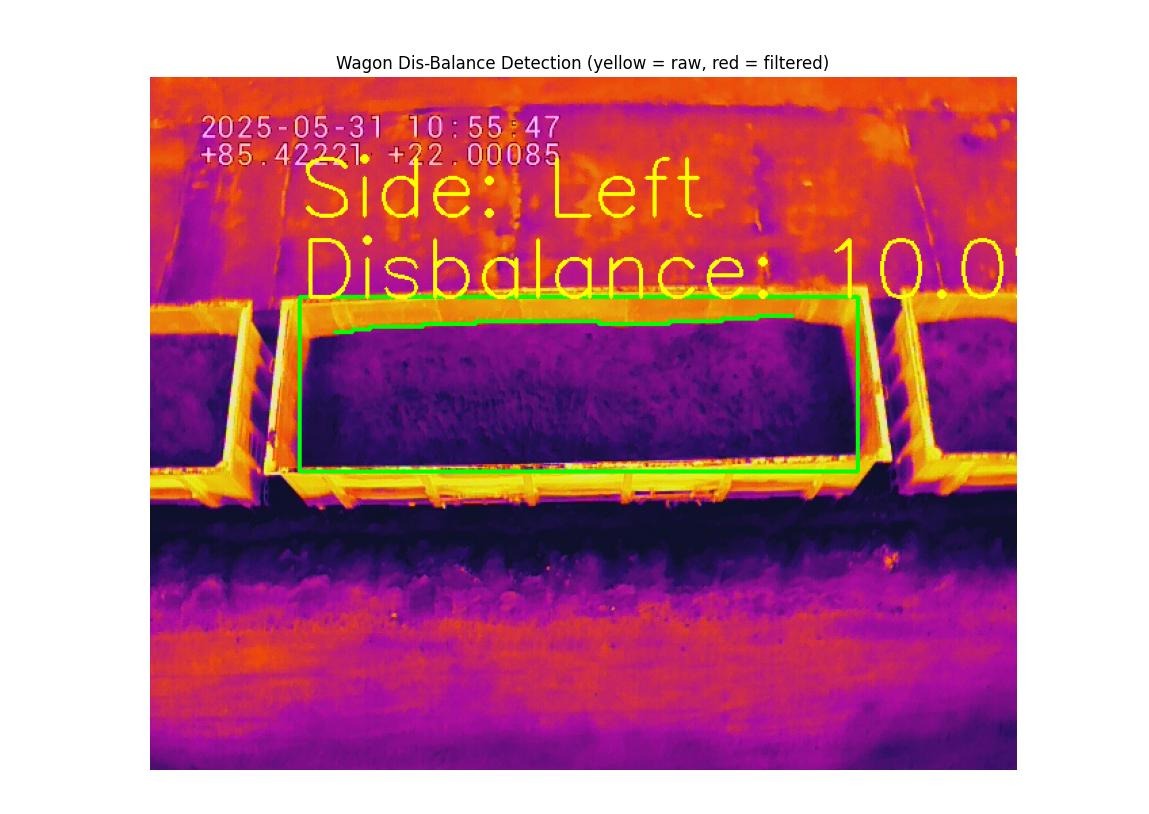

The projects showcases an advanced AI-powered visual inspection system designed for detecting wagon disbalance in railway freight operations. Using thermal imaging and intelligent pattern recognition, the solution enables accurate load symmetry assessment even in complex industrial conditions.

The system delivers automated detection, visual overlays, and detailed analytical reporting — helping operators identify potential disbalance issues before they lead to mechanical strain or safety risks.

Developed for large-scale deployments, it supports batch image processing, automated data logging, and seamless integration with existing monitoring workflows. Its adaptive architecture ensures consistent performance across varied wagon types and environmental conditions.

Future versions aim to introduce real-time processing, multi-angle compatibility, and improved calibration models to enhance precision and operational flexibility across diverse railway inspection environments.

your project into a success story.